Electronic spark tester

Challenge

Intrinsic Safety (IS) is an explosion protection technique for the safe operation of electrical equipment in hazardous areas, like underground coal mines. The method works by limiting the electrical and thermal energy available for ignition. Controlling the risk of spark ignition is a cornerstone of IS, and the use of a standardised spark test apparatus (STA) is often required for safety approval of electrical equipment. The STA has, however, proven unreliable in practice. In two high profile incidents, an approved product failed a retest on the STA, requiring a withdrawal of the product from service at an enormous cost. Despite these incidents occurring more than a decade ago, the questions raised about the STA have not been answered.

Research

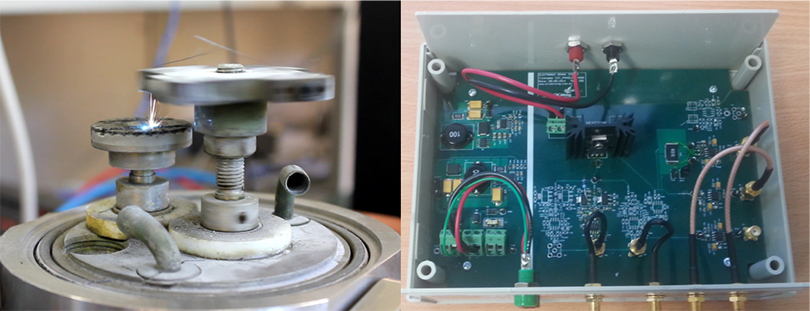

Mining3 is researching an alternative to the standardised STA called the Electronic Spark Test (EST) Apparatus. The STA is predominantly a mechanical device using a real sparking contact and creating laboratory scale explosions to perform tests. Aside from the risk and difficulty this poses to the user, these characteristics are the main reason for the STA’s unreliability.

Unlike the STA, EST does not require the creation of real sparks or explosions. Instead, the effects of a spark on a device under test (DUT) are simulated using a custom designed electronic load. The EST makes a series of measurements of the DUT’s voltage and current response to the simulated spark. The measurements are then analysed to assess the safety of the DUT, based on knowledge of spark and ignition physics developed from experiments undertaken specifically for this project.

The primary contributions of this research to the field of explosion protection are thus a method for electronic simulation of a sparking contact, as well a means for assessing spark ignition risk using electrical measurements.

Benefits

The primary benefit of the EST is its reliability, ultimately contributing to sounder management of explosion risks for end users.

The EST will also benefit manufacturers, as it provides a more informative test result than the STA’s simple pass or fail result. This will enable a better informed design process, potentially reducing time to market for IS products. Additionally, the difficulties in using the STA for newer “smart” power supply unit designs will be resolved with the EST.

The EST’s ease of use will additionally allow intrinsic safety testing to be conducted in various scenarios that were previously infeasible, for example, as part of site of factory acceptance tests.

Overall, the EST is a key enabling technology for a more reliable, versatile and scientifically sound approach to managing spark ignition risk in hazardous areas.

Status

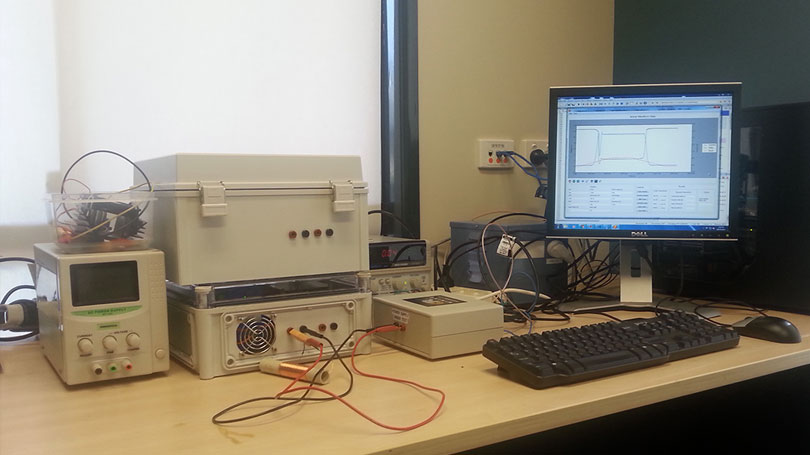

Research into the EST began in 2011 and is currently in its fourth phase. The first phase developed and provided a preliminary demonstration of the EST concept. The results were presented to the International Electrotechnical Commission (IEC) committee responsible for the relevant industry standard. The committee agreed to work with the researchers towards eventual standardisation of the EST, a requirement for wider adoption in the industry.

The subsequent phases of research have focussed on the implementation of the concept and working with manufacturers to ensure that the EST is suitable for use with modern equipment designs.

In September 2015 Mining3’s EST research team received an ACARP Research and Industry Excellence Award for the project.

An advanced research prototype is available for demonstration to interested parties.