The building blocks to In Place Mining

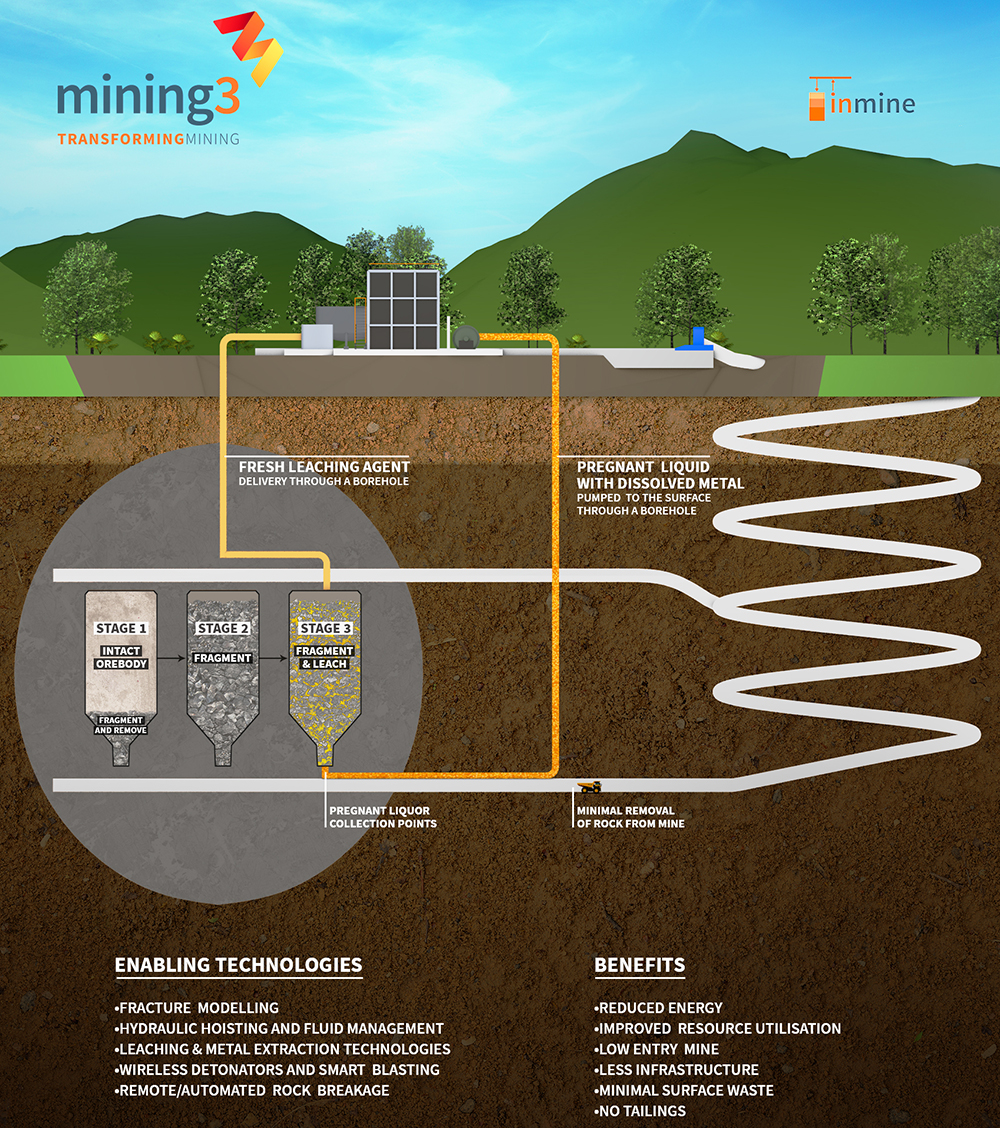

Mining3 is leading a transformational initiative called In Place Mining, which is driven by the concepts of minimal rock movement and processing “In Place”. The intended outcome is a small surface footprint, reduced tailings generation, high automation and a low capital intensity mine.

Three methodologies can be deployed, depending on the orebody and mining method: In Line, In Mine or In Situ. Each is an independent solution, but there are cross-disciplinary linkages that connect them.

In our recent article – “In Place mining – A transformational shift in metal extraction” the full concept was discussed, however, this article is focused specifically on In Mine Recovery.

The In Mine Recovery (IMR) concept is based on minimal rock movement and involves fracturing ore using blasting or hydraulic methods. It utilises some excavation to allow effective fracturing, combined with chemical or biological tools to leach valuable ore under unsaturated conditions.

Rock disturbance would be limited to some form of in place conditioning of the rock mass to allow leaching to proceed.

New methods of rock fracturing

With the advent of wireless detonators, improved blast modelling, sensing, and uphole explosive placement capabilities, new ways of fracturing the rock mass are allowing more effective leaching to take place.

Methods such as Vertical Crater Retreat (VCR) breakage of rock and, a system developed previously by CSIRO called the Remote Ore Extraction System (ROESTM), are options that enable the concept of In Mine Recovery.

Taking surface leaching methods underground

The corrosive effects of sulphuric acid, including environmental and health impacts and its limitation in treating sulphides, have been a barrier to widespread adoption of leaching underground. Whilst sulphuric acid has been used successfully in mines such as Gunpowder in Queensland to leach copper oxides, its use in underground mines would not receive regulatory approval in today’s environment. The recent emergence of non-toxic bio and chemical leaching systems suitable for base and precious metals, however, will enable widespread adoption.

Underground percolated leaching of metals from fractured rock is conceptually similar to surface heap or dump leaching, but with some key differences:

- Temperature: The temperature is likely to be elevated underground depending on which geographical jurisdiction the leaching is taking place. This will generally have a positive influence on leaching dynamics.

- Geometry: A heap leach is typically 6 – 10m high and several hundred metres horizontally. An IMR leach zone would be much taller – 100-150m and narrower – 30-50m.

- Aeration: Surface heaps are open to the atmosphere where oxygen can contact the solution and enable leaching of sulphide minerals. In Mine Recovery may require an alternative oxidant transport mechanism either within the lixiviant or through a mechanical system.

- Particle size: Dump leaching may be on very large run-of-mine ore, or heap leaching on crushed ore as fine as 6mm. IMR fragmented material is likely to be 25 – 50mm. The size distribution of blast-fragmented ore is much narrower than mechanically crushed ore, where a large proportion of fine particles can form.

- Leach time: A single cell in a heap leach may be irrigated for several months or, in rare cases, years. An IMR zone will probably need longer.

- Ore: Heap leaching typically treats near-surface oxides or transitional material which is usually friable and more porous. Conversely, IMR leaching will lead to much deeper operations, where primary mineralisation is prevalent. Oxide material can often break down under heavy loading and cause percolation/permeability issues whereas the primary mineralisation will exhibit more competent geotechnical properties but be harder to infiltrate with lixiviant.

These factors will influence the metallurgical testing and process design. In particular, the geometry will have an impact on percolation rates, aeration, and solution composition.

Economics

The economics of this approach are essentially based on reducing energy consumption through decreasing activities such as:

• Haulage of ore to the surface

• Milling of the ore for metal liberation

• Waste removal

• Developing an extensive surface infrastructure

These equate to over 80% of total operating costs for a standard gold or precious metal mining and processing operation.

In the case of IMR, the break-even point would be the cost of fracturing the ore, pumping, lixiviant regeneration (including top-up for losses) and surface stripping of metal from the pregnant liquor. The lower metal recovery cost would allow for an appropriate profit margin with some preliminary assessments indicating it to be in the range of 20-40%. Metal recovery would, however, be measured over longer periods of time (6-12 months).

The economics of IMR opens up the opportunity to efficiently process marginal ore, and exploit deeper orebodies where natural fracturing in high-stress conditions can be taken advantage of.

Call for collaboration

The In Mine Recovery initiative is a bold new vision for mining. Mining3 is forging collaborative partnerships with interested METS and mining companies to progress it.

There will be an initial feasibility study of IMR as an alternative to conventional extraction methods, with an additional objective to consider a way of increasing the life of a mine through mining of marginal grade ore.

The study will enable:

-

- Mining companies to understand the feasibility and the potential impact of IMR on existing and new mines.

- METS companies to identify opportunities for the development of new products and services as well as applications for existing products.

- Consultants to understand the options and develop detailed feasibility studies for resource asset owners.

- Equipment manufacturers to consider new types of equipment.

The project will provide many of the answers to questions that arise from taking IMR from a concept to a feasibility readiness level. Contact Mining3 at info@mining3.com for further information.